Head Gasket Repair

With the cylinder head removed, the remaining head gasket material and piston can be cleaned. I use the proper tap to clear out any foreign material that may have fallen into the head bolt threads.

A paper towel or clean rag is placed in the cavity where the intake and exhaust push rods are located so no debris falls into the bottom of the engine block.

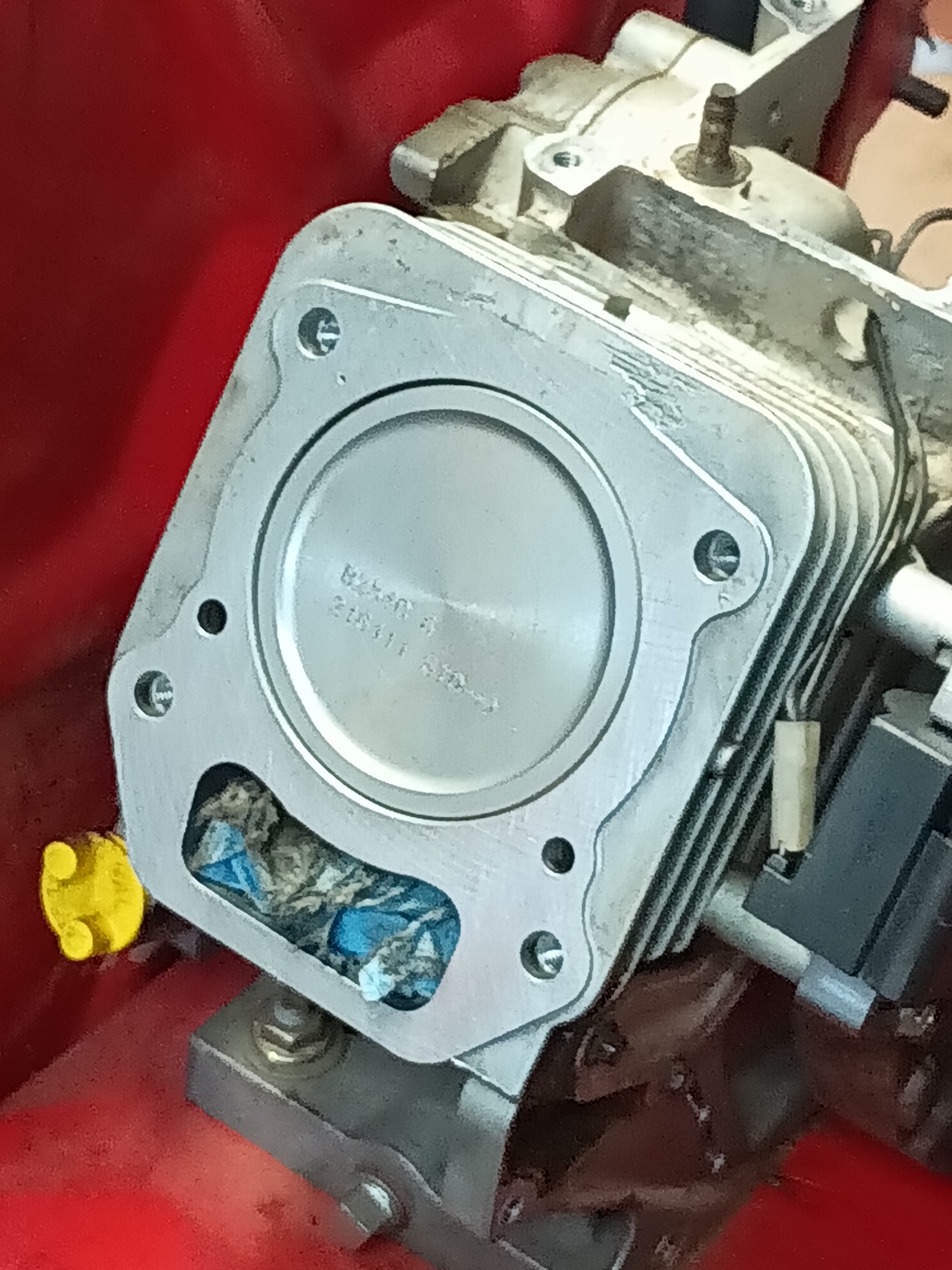

The cylinder has 2 guide sleeves that will be removed from the head and inserted into the holes diagonally on the cylinder. With this cylinder cleaned up, a new head gasket can be placed over the guide sleeves and the cleaned cylinder head with it's bolts which now can be torqued to spec. The 2 push rods can be added later.

Nest Removal

With mowers being stored outdoors or in a shed for a long period of time usually during a winter, mice and other rodents will make a home underneath the cowling or engine cover.

These nests have to be removed right away to prevent overheating of the engine and further damage with eaten wires.

It can also be a fire hazard being so close to the exhaust and muffler. So how do you know if you have a tenant under your hood, you don't because they are long gone when you move the machine in the spring. But sometimes you could see them come out and run for the border. Look for grass poking out for signs of a nest.

Camshaft and Governor

The camshaft (large gear) and the governor (small gear at top) are damaged and require replacment. Some newer Briggs & Stratton engines have a plastic camshaft and need replacement more often.

Camshafts provide the timing of intake and exhaust valve openings and have to be exact. The camshaft is driven from the crankshaft and both have timing marks that have to be aligned when reassembled.

The governor gear is driven by the camshaft and regulates the speed of the engine providing smooth operation.

"L" Head Cylinder

This single cylinder doesn't have any push rods and uses the valve stems instead. The cylinder was honed to recreate a cross hatch pattern so that the piston rings can provide a good seal and compression.

The intake and exhaust valves will be lapped or ground using a special gritty paste so they have a good mating seal on the cylinder valve seat. The paste has to be cleaned off thoroughly to prevent further grinding of the parts.

The threads in the cylinder as well as the bolts will be cleaned with a tap and die. The cylinder is now ready to be reassembled with the valves, a new head gasket and the cleaned cylinder head.